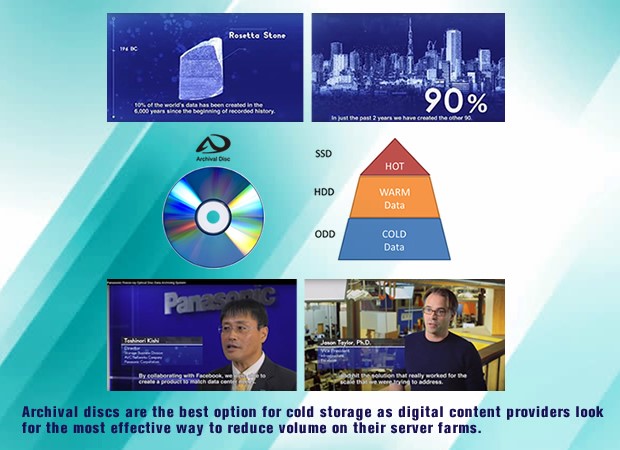

Every time you send an email, post a picture on social media (like Facebook), or send a snarky message through Twitter, and so on, you leave a digital footprint that is kept and stored by the platform you’re using. That means that companies like Facebook, Google, WhatsApp, etc. need to maintain adequate server farms to hold not just recent data storage, but also years of previous data. That old content is referred to as “cold data” because it’s rarely retrieved and essentially on ice until it’s needed again. Since cold data is not accessed frequently, to free up space for current and future content, the cold data is often offloaded onto another digital platform that can be easily stored, retrieved, and doesn’t take a lot of space, both physically and electronically. That makes optical discs the ideal storage medium for Cold Data as it fulfills all of the requirements.

In 2016, the thinktank IDC concluded that the world’s data storage stood at 16ZB, (that’s Zettabytes, with a “Z”, which is 1 trillion Gigabytes, that’s trillion with a “T”). Based on current and expected future internet usage, the IDC anticipates that number to increase to 163ZB’s by 2020. That means in 4 short years, we would have all contributed nearly 150 more Zettabytes or 150 trillion GB’s of digital content held in electronic storage. Based on these numbers, it’s expected that even if only 10% of that content needs to be offloaded onto Archival Discs (AD), which currently hold 300GB each, it would take roughly 800 million AD’s to hold that content resulting in a windfall of approx. USD $3 billion in revenue for the company(ies) that can tap into this growing market. That is just the tip of the iceberg in terms of potential for the AD market. So, this is the perfect time to get in and take advantage of the future of the optical evolution. That is just the tip of the iceberg in terms of potential for the AD market. So this is the perfect time to get in and take advantage of the future of the optical evolution.

For more details about archival storage or any product in the Vinpower offering, please visit our website at www.vinpowerdigital.com, or contact a representative near you.